De Single screw extruders van Twin Tech zijn geschikt voor het processen van de meeste grades zoals HDPE, LDPE, PVC, ABS, PC, PS. Wij leveren individuele extruders maar ook downstream machines en complete lijnen voor pipe-, profile-, en sheet-extrusie. Twin Tech machines kunnen voorzien worden van manuele of volledig geautomatiseerde controls met PLC sturingen die integratie in bestaande lijnen mogelijk maken

De Single screw extruders van Twin Tech zijn geschikt voor het processen van de meeste grades zoals HDPE, LDPE, PVC, ABS, PC, PS. Wij leveren individuele extruders maar ook downstream machines en complete lijnen voor pipe-, profile-, en sheet-extrusie. Twin Tech machines kunnen voorzien worden van manuele of volledig geautomatiseerde controls met PLC sturingen die integratie in bestaande lijnen mogelijk maken

Our Single screw extruder are built with various kinds of screw designs and compression ratios according to different raw material and applications.

With accurate and precise control of temperatures and drive, The TTE Single serie is fitted with user-friendly control system that saves all essential process parameters, making them accessible for several types of evaluations.

The large number of screw diameters available (12mm, 18 mm, 20 mm, 25mm, 30 mm, 45 mm, 60mm) allows you to choose from economical machines for a wide range of applications.

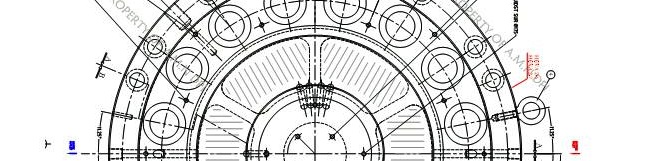

Basic version of our extruders features a three-zone screw with an L/D ratio of 25:1 and equipped with a:

Frequency-controlled three-phase motor

Bevel gear drive and Thrust bearing with drive

Barrel with water-cooled zone (either feed zone or entire barrel)

Hopper with slide gate

4 barrel heating zones, barrel cover

Barrel material: nitrided steel or stainless steel

Up to four heating zones and five die zone can be controlled and displayed. Melt temperature and melt pressure as well as screw rpm and torque are also displayed.

The TTE12 S has a throughput of about 0.5 kg/h, while that of the E 30 E is about 14 kg/h.

Compact design and convincing technical features make these machines the ideal solution for applications in laboratories and small-scale production e.g. food-, building-, and pharmaceutical industries.